Leaders Unloaded: A Conversation with Jake Ganor, Adept Armor’s Visionary Founder

By Ashley Burgess Gall, Laura Burgess Marketing

In the world of armor technology, where protection can mean the difference between life and death, Adept Armor stands as a beacon of innovation and excellence. I had the privilege of sitting down with Jake Ganor, the mastermind behind Adept Armor, to delve into the inspirations, methodologies, and aspirations that have propelled his company to the forefront of the industry.

In the world of armor technology, where protection can mean the difference between life and death, Adept Armor stands as a beacon of innovation and excellence. I had the privilege of sitting down with Jake Ganor, the mastermind behind Adept Armor, to delve into the inspirations, methodologies, and aspirations that have propelled his company to the forefront of the industry.

Ashley Burgess Gall (ABG): Adept Armor has made a significant impact in the armor technology space. Could you share the inspiration or moment that led you to found the company, and what specific gap in the market you aimed to address with your innovations?

Jake Ganor (JG): The company started, about ten years ago, due to work on a compound called cubic boron nitride (cBN). As a chemist, I was researching organoboron compounds, but I was also doing work with hexagonal boron nitride. This eventually led to some work with polycrystalline cBN (cBN), which is an extremely hard material, far harder and tougher than boron carbide. At this point, it occurred to me that cBN might make for outstanding hard armor plates. There was no data, but I was curious enough to research this independently. I quickly also branched out into polycrystalline diamond materials, which we still do extensive work with.

It turns out that cBN doesn’t really perform any better than boron carbide, and in fact seems to perform worse in the thickness ranges characteristic of body armor. This is because cBN, though lighter than alumina and not much denser than silicon carbide, is still relatively dense; an 8mm thickness of cBN has equivalent mass to a 10.72mm-thick tile of B4C. On an equal weight basis, against common threats, it’s the thicker tile that performs as well or better. This was experimentally shown in a US Army Research Labs paper published a couple of years after we started our own work with cBN.

We’ve since developed a mathematical model for quickly predicting ceramic performance from thickness, density, and a few other parameters. I’ll publish it later this year.

Anyway, we moved from experiments with cBN to experiments with other armor materials, including “traditional” armor materials like SiC. The goal is to improve their performance by improving their chemistry and then optimizing their use in composite systems. One thing led to another, and now we’re practically a vertically integrated research-design-manufacturing house.

ABG: Adept Armor is known for its cutting-edge armor solutions. Could you discuss one of the most revolutionary advancements your company has introduced and how it has changed the landscape of personal protection?

JG: The biggest advances in hard armor are yet to come and are in fact scheduled for 2024, but I think that the glass-ceramic strike-face in our Thunder RF2 plate is the biggest innovation the industry has seen in some time, at least where plates are concerned.

With the release of NIJ 0101.07 and the standardization of test threats across all NIJ ballistic specifications, there’s sure to be more demand for plates at the RF2 level. These plates hit the sweet spot for domestic police and security use. RF1, which doesn’t protect against ubiquitous M855 and might have trouble with mild steel core rifle threats that impact at a 30° angle, clearly isn’t enough. RF3(+) plates tend to be heavy and are overkill for the common threats one might encounter domestically. The optimal choice for almost all purposes is a lightweight RF2 plate, and it’s hard to do much better than one that weighs 3.4 pounds and offers edge-to-edge protection. It’s difficult to hit that weight point with conventional ceramics.

With the release of NIJ 0101.07 and the standardization of test threats across all NIJ ballistic specifications, there’s sure to be more demand for plates at the RF2 level. These plates hit the sweet spot for domestic police and security use. RF1, which doesn’t protect against ubiquitous M855 and might have trouble with mild steel core rifle threats that impact at a 30° angle, clearly isn’t enough. RF3(+) plates tend to be heavy and are overkill for the common threats one might encounter domestically. The optimal choice for almost all purposes is a lightweight RF2 plate, and it’s hard to do much better than one that weighs 3.4 pounds and offers edge-to-edge protection. It’s difficult to hit that weight point with conventional ceramics.

ABG: Comfort is often a concern when it comes to wearing armor. How does Adept Armor strike a balance between offering top-tier protection and ensuring that wearers can move comfortably and confidently?

JG: In armor plates, it’s simple: we don’t release any plates that aren’t multi-curved. That aside, comfort has more to do with the load-bearing and weight-distribution features of the armor carrier. The most we can do, right now, is to release plates that are multi-curved and as light as possible.

In other products, such as helmets, riot armor breastplates, etc., it’s an iterative process that involves anthropometric sizing data. These are first used in a CAD model, which informs the first prototypes. Those prototypes are made and tested for comfort and are generally refined a few times before we release the finished product.

ABG: Designing advanced armor likely involves close collaboration with experts from various fields. Could you share how Adept Armor harnesses interdisciplinary expertise to create products that meet both technical and user-centric requirements?

JG: I’m a devotee of a design philosophy called parametricism, as outlined by architect-philosopher Patrik Schumacher in his books The Autopoiesis of Architecture I and II, which emphasizes the use of computational design strategies to dynamically adapt and optimize architectural forms based on a set of parameters influenced by geometry, materiality, and environmental conditions. It’s not limited to architecture; in the context of armor design, this philosophy underpins Adept’s approach to harnessing interdisciplinary expertise in the creation of advanced systems.

Here’s how we integrate this philosophy:

Parametricism promotes a fluid and adaptable design process, which we mirror in our collaborative approach. By establishing a parametric model as our common language, experts from various fields such as material science, biomechanics, ergonomics, manufacturing, and terminal ballistics can contribute their specialized knowledge in a coherent and integrated manner. Each discipline inputs parameters based on their expertise, influencing the design in real-time to meet both technical and user-centric requirements. The parametric design process is inherently iterative, allowing for the continuous refinement of our products.

The synthesis of interdisciplinary knowledge within a parametric framework leads to innovative solutions that might not emerge in a siloed approach. Most critically, it also ensures that we’re not leaving any material “on the table,” so to speak. We use whatever works, whether it’s steel, aluminum, magnesium, UHMWPE, ceramics, 3D-printed plastics, pool-noodle foam, you name it. We don’t follow trends; we input carefully considered parameters within the context of a problem we need to solve, and we let those parameters dictate the form and function of the solution in an iterative and wildly associative process.

The term is badly overused, but a lot of firms “cargo cult” armor design. They use materials and system configurations that they’ve seen other companies use, and they figure out that it works, but they don’t always understand why or how it works, and they don’t know how to improve upon it. We do things differently.

In essence, a dedication to an iterative parametric design process enables us to efficiently leverage the full spectrum of interdisciplinary expertise.

ABG: Threats and risks can change rapidly. How does Adept Armor stay agile and adaptable to emerging threats to continue providing effective protection solutions?

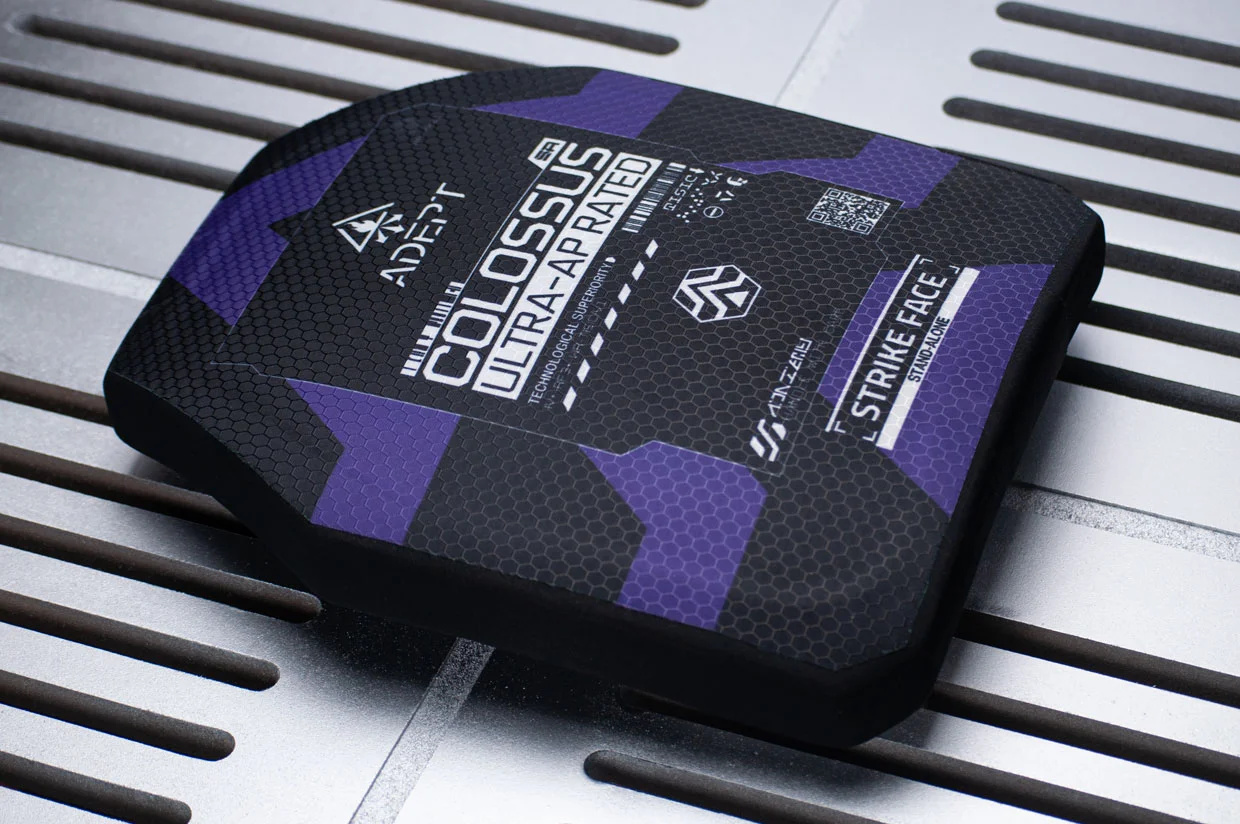

JG: That’s largely a specification problem. When building armor systems to the NIJ specs, or military specifications, emerging threats are not always taken into consideration, and there’s little we can do about it. Products like the Colossus plate and the NovaSteel Breastplate are, each in their own way, attempts to push back on the specifications a little bit, but ultimately military planners and NIJ researchers are the ones who set the tone. Sometimes they take our advice, sometimes they don’t.

I will note, however, that we have in-house mathematical and computational models that are highly adaptive to changing parameters. Adept Armor employs these models to simulate and analyze the performance of armor under various threat scenarios, and this enables pretty rapid in silico prototyping against novel threats.

ABG: Personal protection and armor technology can have ethical implications. How does Adept Armor approach ethical considerations in terms of the uses of its technology and ensuring responsible application?

JG: It is important to emphasize that Adept is solely and exclusively focused on body armor research, development, and production, which is all completely defensive in nature. Body armor is a technology that not only doesn’t kill, it saves lives; instead of causing bloodshed, it prevents it. This isn’t only true in war, either; in this age of terrorism, civilian lives are often at risk as well, even in places far from any battlefield. This means that improved armor can save the lives of both soldiers and civilians, during times of both war and peace. And, indeed, it is not only military and police forces who are interested in our products; we’ve also supplied charities and humanitarian organizations with plates and helmets. We hope to work closely with humanitarian landmine removal organizations, and there are a lot of journalists in war zones right now using our products.

In my opinion, armor production is a noble and ethical use of research in the materials sciences. It is something that any organization can be proud to be a part of.

ABG: As a founder and innovator, what advice do you have for aspiring entrepreneurs and inventors who seek to make a positive impact through groundbreaking technological advancements?

JG: Don’t chase trends. Unless you’re just looking for research funding and are happy to waste time, it’s always a bad move. The carbon nanotube, for instance, has done far more harm than good for armor science. “Liquid” (shear-thickening) armor is even worse. A totally inordinate amount of time and research funding, possibly millions of man-hours, have gone into chasing these trends, with virtually nothing to show for it. This is despite the fact that the CNT is 33 years old, and the first liquid armor patent has already expired due to old age.

If 1/10th of that effort had, instead, gone into new polymers like, e.g., stable Zylon derivatives, possibly with imidazole rather than oxazole moieties, we’d probably have a lot of cool new armor materials now.

So, my advice would be to ignore pop-sci press releases and look at the fundamentals.

Chemistry is the most important discipline. You don’t really need to know advanced mathematics, computational modeling, parametric design tenets, etc., but it’s tough to really innovate in this sector without understanding chemistry. It may be impossible. Metallurgy, ceramic science, polymers and composites, and resins are all downstream of chemistry.

ABG: What advice would you give to young engineers aspiring to become successful leaders in their respective fields?

JG: My advice to engineers is to specialize early, and to focus on a problem rather than a potential solution. A peculiar failure mode is when an engineer or engineering team falls in love with a specific solution, like a material, and then discards or fails to consider possible alternatives. One sees this a lot in our industry, and in fact, the Kevlar helmet is an excellent example. It is best to hyper-specialize in a problem and then fairly evaluate inputs that purport to solve that problem.

Let me give you an example: Titanium metallurgy. How many Americans (or Europeans, for that matter,) are specialists in titanium metallurgy? Extremely few. You could count the good ones on one hand, and they’re all about ready to enter retirement. Humanity hasn’t made or tested even the barest fraction of possible titanium alloys; the field is rewardingly complex; there’s a growing demand for strong titanium alloys, not only in armor and military equipment but also in consumer products, e.g. the latest generation of smartphones. This is all very fertile ground: a young professional engineer could, with what I’d consider reasonable individual effort, make a name for himself.

It can look difficult to reconcile my seemingly contradictory first and second paragraphs, but “problem” doesn’t need to mean “product category.” It’s very much a problem that ultra-high-strength/high-hardness titanium alloys aren’t available to industry, though they are, emphatically, theoretically possible to produce, and indeed I’ve seen 50-year-old reports of Ti alloys in the 60+ Rockwell C range.

The “problem space” for young engineers is vast. Here’s an even better example: I’m absolutely dead serious when I say that there are less than five people on Earth who have the vaguest outline of how soft armor really works and, in general, there are so many open scientific questions surrounding it that they could keep a dedicated soft armor engineer very active for many decades, assuming AIs don’t come along and answer all of them for us in five years. I suppose there’s now that risk. The underlying physical dynamics are simply not understood, though a famous researcher by the name of Phillip Cunniff did an outstanding job of elucidating and defining the various issues. The computational models are, at their very best, poor for predictive applications. There’s a large unexplored possibility space in the chemistry of polymers, resins, and their interface which makes for three separate areas of study. It is not known how performance against the .44 Magnum SJHP relates to performance against the 17gr. FSP across soft armor system types, save to say that they’re dissimilar. And I could go on all day. Not only are these important and interesting questions but uncovering answers is likely to be financially rewarding.

Now, having said that, problems can be well-structured or ill-structured. Ill-structured problems lack clear goals, lack definitive solution paths, and often involve complex interdependencies that defy straightforward analytical approaches. Focusing R&D on improving the strength of titanium alloys involves working toward the solution of a well-structured problem. Design problems, in contrast, are always ill-structured problems and a lot of open questions surrounding composite systems and system integration are very ill-structured. It’s best to be aware of this and to work toward something that suits your temperament as well as your interests.

Ultimately, what I’d highlight is the importance of specializing early, defining problems in their complexity, and exploring a wide array of potential solutions without preconceived biases toward particular materials or techniques. What I’d encourage is an openness to out-of-the-box ideas and a commitment to exploring the depths of a problem space.

ABG: If you could go back in time, what advice would you give your younger self as you started your career journey?

JG: There are six things I would tell my younger self. They are:

(1) Embrace complexity: Understand that military systems engineering, and indeed any scientific/technical field, is an inherently complex domain that requires you to navigate, understand, and leverage complexity rather than oversimplify. Early on, recognize the value of engaging deeply with the multifaceted aspects of your work.

(2) Innovate through technology: Invest time and effort into mastering new technologies and digital tools. The future of engineering product design is inextricably linked with advancements in computational design, simulation, and fabrication technologies. Being at the forefront of these can set you apart.

(3) Engage with the avant-garde: Seek out and engage with cutting-edge practices, theories, and materials. This is not about being different for the sake of being different; it’s about finding and implementing novel concepts that push the boundaries of what is known and accepted, thereby contributing to the evolution of your field.

(4) Adopt a critical stance: Always maintain a critical perspective toward existing norms and practices (e.g. the aramid helmet). This will not only help in identifying areas ripe for innovation but also in developing solutions that are deeply reflective and responsive to the nuances of the problem at hand.

(5) Focus on interdisciplinary collaboration: The challenges of contemporary engineering and design are too complex to be addressed from a single disciplinary perspective. Collaborate across disciplines to enrich your understanding and create more comprehensive, effective solutions.

(6) Network and community building: Be proactive in building a network of peers, mentors, and collaborators. Loosely coupled networks of professionals are very often responsible for achieving significant breakthroughs.

ABG: Looking ahead, what legacy would you like Adept Armor to leave in the realm of personal protection and armor technology?

JG: We’ve just gotten started. It’s far too early to talk about legacies, but I know what the near future looks like. I cannot talk much about it just yet, but I’ll drop a hint: the future is in total integration and a much larger area of coverage. I’d like to see our gear used on Mars before I’m through.

The post Leaders Unloaded: A Conversation with Jake Ganor, Adept Armor’s Visionary Founder appeared first on Laura Burgess Marketing.

Responses